SIGMASTER

strongest solution of SIGMAFA

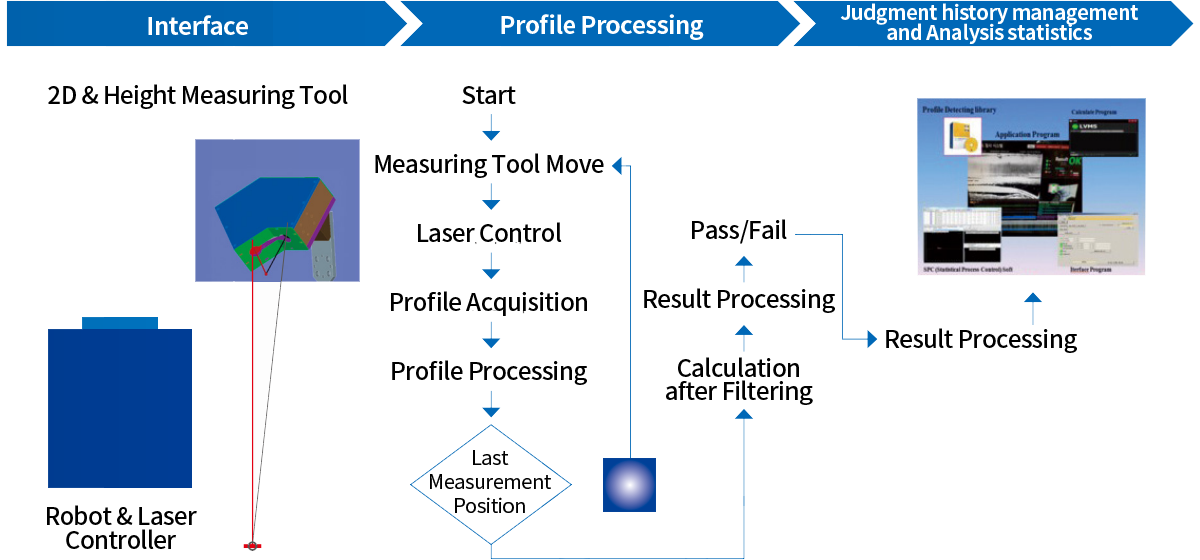

What is Sigmaster system?

Quality keeper SOFTWARE PACKAGE that perfectly compares/judges MASTER/inspection products by setting the 3D drawing of the product to be produced as the standard master and measuring the product to be inspected in 3D

Inspection items

-

Dimension inspection

-

Missing / Heterogeneous test

-

Welding Bead Inspection System

-

Robot visualization

PICK & PLACE -

Integrated system

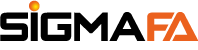

Welding Bead Inspection System

It is a system that analyzes the shape of the welding bead by 3D SCAN and measures the welding length, bead cross-section area, throat thickness, leg length, etc. to judge the welding quality.

Learn more

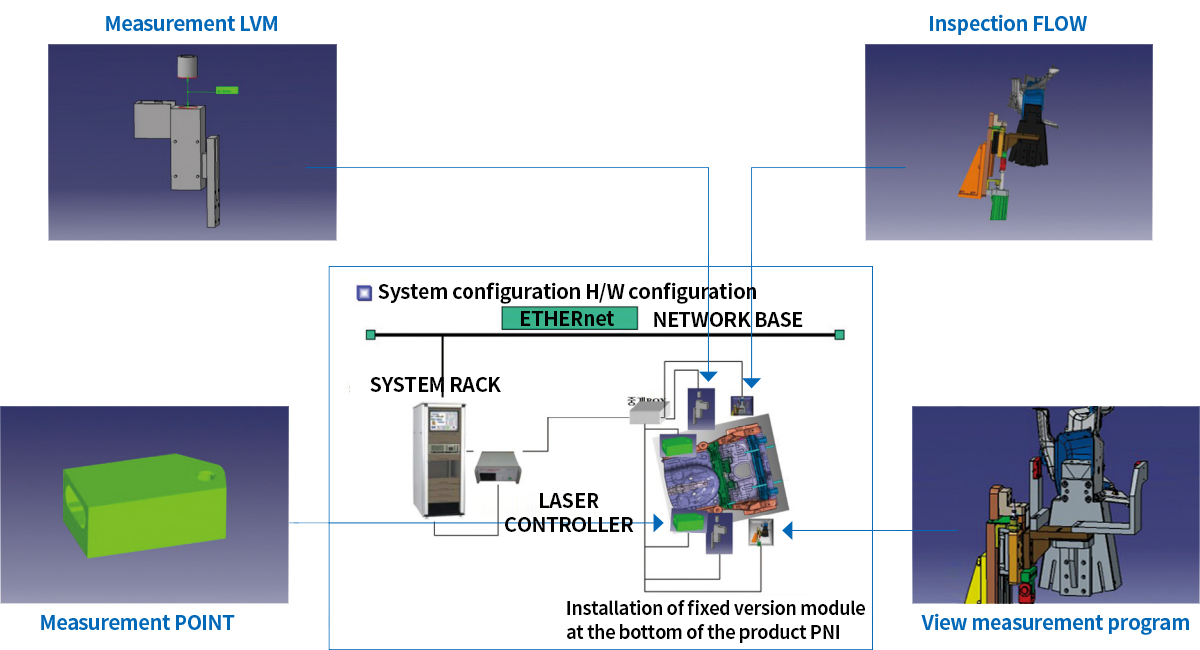

3D MEASUREMENT SYSTEM

3D measurement is the instrumentation process of collecting 3D data from physical objects such as shape, texture, geometric features, and color using various types of 3D measuring tools, such as 3D scanners.

Learn more

Stationary 2D VISION measuring system

It is a system that makes pass/fail judgment based on the deviation value between the point measured in the MASTER Image of the product to be inspected and the point measured in the current image.

Learn more

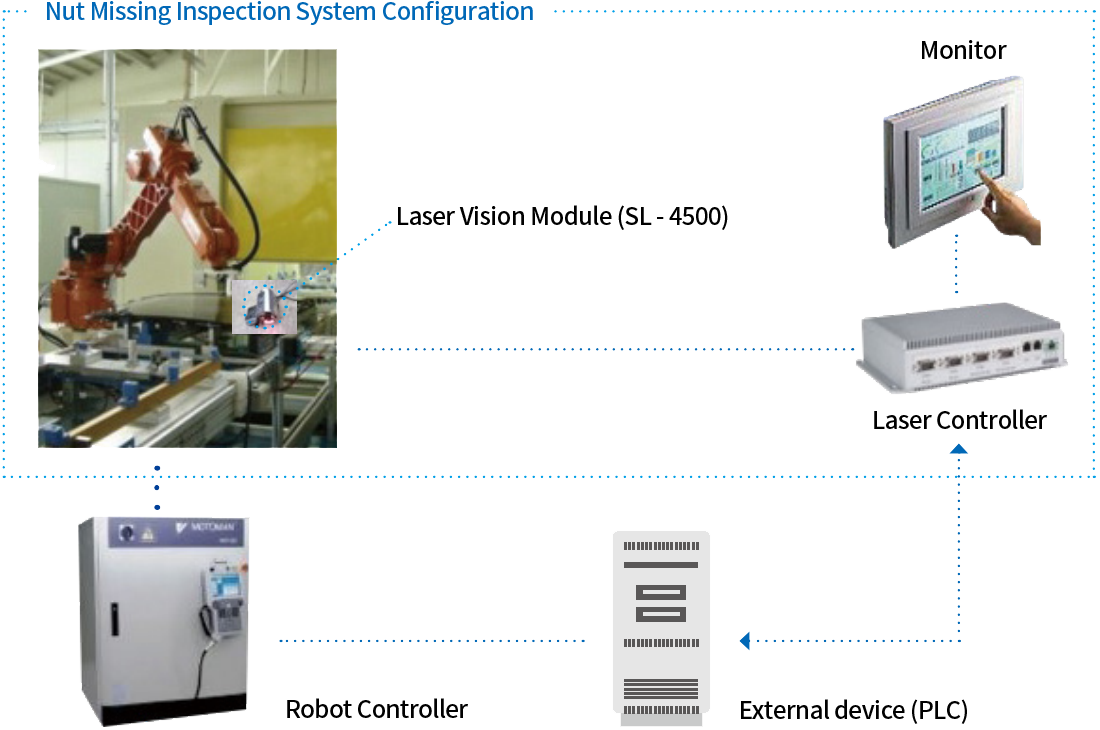

Missing Vision Inspection System

It is a quality keeper that guarantees perfect quality by scanning the shape of a product with a 3D SCANER and analyzing it with SIGMASTER, a shape analysis algorithm, to see if there are any missing parts or if the dimensions are satisfied.

Learn more

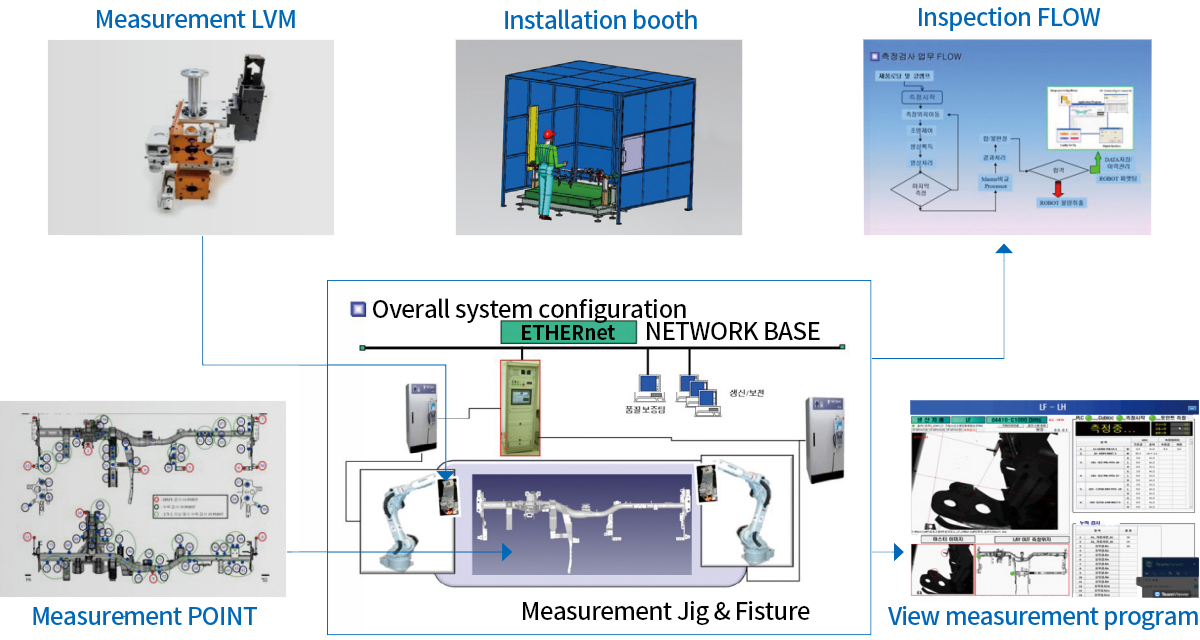

Cowl Cross Vision Inspection System

As a system for inspecting the quality of cowl crossbars among automobile parts, it performs MDPS measurement, absolute distance between guide pins, inspection of various parts for omission, and inspection of the correct position of stud bolts.

Learn more

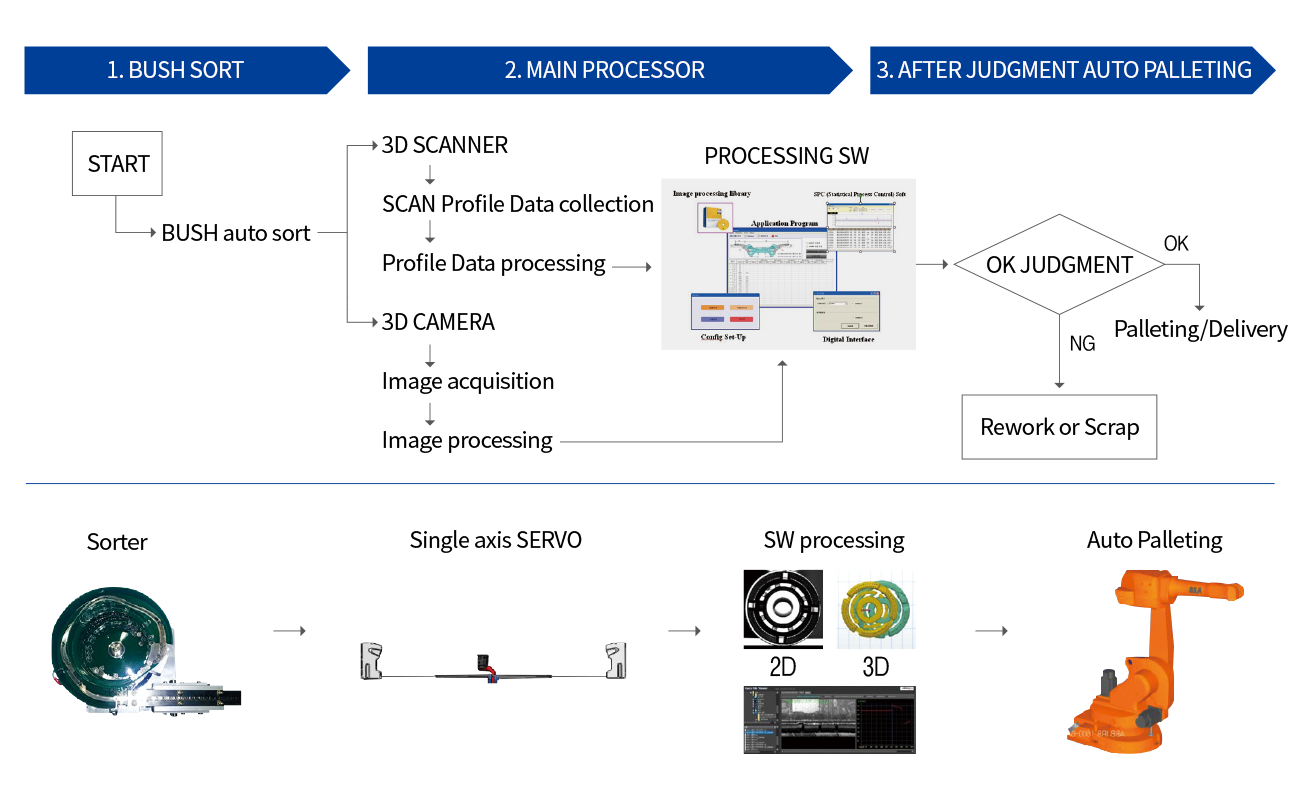

PICK & PLACE SYSTEM

It is a system that 3D scans the product to inspect the quality, judges good or bad, and separates it into a pass box and a bad box, respectively.

As a perfect quality keeper through deep running, it is a system that can realize cost reduction by replacing multiple quality inspectors.